KIOGE-2014

TCO: World-Class Operations with Minimum Impact to Environment

TCO: World-Class Operations with Minimum Impact to Environment

TCO: World-Class Operations with Minimum Impact to EnvironmentTengizchevroil (TCO) is a major producer and marketer of crude oil in Atyrau Oblast, a region of Western Kazakhstan, where the company operates the giant Tengiz and nearby Korolev fields. In 2008, TCO completed the Sour Gas Injection and Second Generation Plant (SGI-SGP) expansion, which increased daily crude oil production capacity to more than 75,000 tonnes (600,000 barrels). In addition to crude, TCO produces liquefied petroleum gas (LPG), butane, propane and elemental sulfur.

Tengizchevroil is committed to the safety, environmental protection and well-being of the communities where it operates. Due to this commitment, TCO continues to focus on environmentally-friendly practices and strictly adheres to the laws and regulations of the Republic of Kazakhstan, as well as global standards.

To the questions of PETROLEUM magazine answering Robert Guldner - General Manager of Operational Excellence / Health, Environment and Safety, Tengizchevroil LLP

– Mr. Guldner, what are the priority areas of TCO on the environmental issues? And what progress has your company made under the environmental program?

– Environmental protection is a top priority at Tengizchevroil (TCO). TCO strives to achieve optimal results in environmental protection through a continual focus on the operational excellence of our processes.

We are committed tocontinually improving freshwater conservation and wastewater discharge compliance, reducing air emissions, and reducing waste while promoting recycling and reuse.

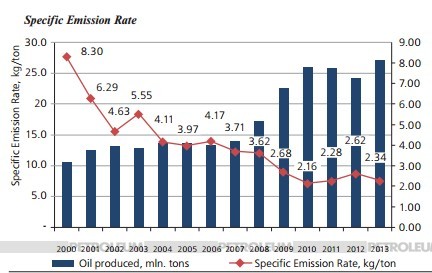

TCO has made great strides in reducing air emissions by implementing a portfolio of major capital projects in Tengiz. Our significant reduction in kilograms of air emissions per tonne of hydrocarbon produced from 2000 through 2013, is an example of what our efforts have achieved.

TCO: World-Class Operations with Minimum Impact to Environment

TCO: World-Class Operations with Minimum Impact to Environment– Please, tell us about TCO’s gas utilization program and freshwater management?

– Since 2000, TCO has achieved many positive results. We eliminated routine gas flaring in 2009, increased the gas utilization volume by more than 99%, and over a ten-year period reduced the volume of gas flared by 93%. Note that these flaring reduction results were achieved while production volumes increased 158 percent. TCO was recognized by the Global Gas Flaring Reduction partnershipof the World Bank in 2012 as a world leader in reducing gas flaring.

The reduction of emissions is a direct result of a continuous adherence to the TCO Environmental Protection Strategy, which included the implementation of the following projects:

- Gas Processing Capacity Expansion (2001);

- Gas Pipeline Capacity Increase (2002);

- New Commercial Gas Pipeline (2005);

- Replacement of Flare Tips (2007);

- Integrated oil projects (2008);

- Gas Utilization Project (2009);

- Acid Gas Flaring Project (2012);

- Liquid extraction and SGI system purge projects (2013)

Regarding water, TCO is a leader in the field of water resources management. Conservation of freshwater through reuse and recycling practices is a key part of TCO’s water management plan, focusing on sound water management practices to achieve business and environmental performance objectives.

The TCO Water Management Strategy project will identify technically feasible alternative water supplies that will enable TCO operations to further reduce fresh water consumption from the current pipeline.

In 2013, TCO commissioned the new WastewaterTreatmentFacility, which is designed to treat 6000 m3/day of municipal wastewater. This facility utilizes Sequenced Batch reactor technology to treat sanitary wastewater and is one of the largest wastewater treatment facilities in Kazakhstan. The new WaterRecycling Facility, currently under construction, is designed to treat up to 5000 m3/d of effluent from the Wastewater Treatment Facility to achieve technical water quality via reverse osmosis. The new Water Recycling Facility can produce up to 3600 m3/day of recycled water that will be used for TCO’s industrial operations. The recycled water from the Water Recycling Facility operation is expected to increase TCO’s annual recycled water rate to 30%. At full production, this allows TCO to reduce its technical water consumption from current usage rates for current operations by 1.3 million cubic meters per year.

TCO: World-Class Operations with Minimum Impact to Environment

TCO: World-Class Operations with Minimum Impact to Environment– What modern technologies are used by TCO to reduce environmental impact, optimize the use of natural resources and for waste management?

– TCO is focused on increasing the volume of the waste we recycle as part of the Green Economy initiative.

At our Integrated Waste Management Facility we not only have world class municipal and industrial landfills with leachate protection and groundwater monitoring, but we treat and process multiple other wastes.

Concrete wastes are processed through our rock crusher unit and the resulting materials are used to construct roads and embankments for waste disposal cells at our landfills. Since commissioning in 2009, the rock crusher has processed 27,000 tonnes of concrete to reusable crushed rock.Tengizchevroil (TCO) is a major producer and marketer of crude oil in Atyrau Oblast, a region of Western Kazakhstan, where the company operates the giant Tengiz and nearby Korolev fields. In 2008, TCO completed the Sour Gas Injection and Second Generation Plant (SGI-SGP) expansion, which increased daily crude oil production capacity to more than 75,000 tonnes (600,000 barrels). In addition to crude, TCO produces liquefied petroleum gas (LPG), butane, propane and elemental sulfur.

Treatment and disinfection of medical wastes on Newster 10 unit

Treatment and disinfection of medical wastes on Newster 10 unitTCO operates a horizontal baler to reduce the volume of wastes such as HDPE containers and waste cardboard in preparation for offsite shipment and recycling.

A Newster 10 unit located on TCO Integrated Waste Management facility is used to treat and disinfect medical wastes. The treatment process includes pulverizing the wastes, applying heat and steam, then disinfecting with sodium hypochlorite to sterilize the wastes, reducing it to a hazard class V.

At TCO we use a state of the art Thermomechanical Cuttings Cleaner (TCC) thermal desorption process to treat drill cuttings which were drilled with oil based (diesel) mud. The diesel is recovered from the drilling mud and then reused in the drilling process and the resulting solids are sent off site to a third party for bioremediation.

With the intent of increasing the amount of recycled wastes and decreasing the amount of natural resources consumed, TCO is focused on the development of a waste recycling segment within the RoK economy. TCO is currently sending more than 20 types of waste for recycle to nine separate processing companies within RoK.

1

1Regarding our further reduction of flaring, TCO is the first company in Kazakhstan licensed to use the YOKOGAWA Exapilot software, designed to reduce gas flaring. This automated software was introduced at our KTL plant and it ensures a timely response to a sulfur unit shutdown, decreasing the likelihood and amount of acid gas flaring.

I have given just a few examples of our use of the latest technologies in our operations intended to recue TCO’s environmental impact.

– What measures does TCO conduct on landscaping territory where it operates?

Carrying out works on landscaping has important ecological effect, including prevention of erosion processes, improving wildlife habitat and a positive effect on the maintenance of biodiversity.

TCO has landscaped in the SPZ in Tengiz, an area of over 100 hectares, which includes planting on more than 25 hectares over the last 3 years. These works have contributed to the reduction of desertification and to the improvement of the existing ecosystem. The planting material is mainly represented by such species as black saxaul and tamarisk.

TCO: World-Class Operations with Minimum Impact to Environment

TCO: World-Class Operations with Minimum Impact to EnvironmentConsidering the high degree of aridity, salinity, carbonate content, low capacity of desert soils, planting and caring for plants require special attention. The current survival rate is acceptable under the circumstances.

In 2012, in order to increase the survival rate of seedlings in the local soil and harsh climatic conditions, a nursery was created for growing saxaul seedlings for acclimatization and subsequent transportation to suitable areas.

In 2011, TCO initiated the project "Study of the Possibilities of Landscaping in Zhylyoi Region." The objective of the project is to improve the environment and increase the aesthetic value of communities in Zhylyoi Region of Atyrau Oblast.

In 2013, within the scope of this project, TCO started a pilot landscaping project in Zhylyoi Region. Two-thousand seedlings of elm, maple and ash were planted in areas specified by Zhylyoi Region and Kulsary town akimats, including Dostyk Park in Kulsary that has become a favorite leisure spot for the community and subject of special pride for TCO.

TCO: World-Class Operations with Minimum Impact to Environment

TCO: World-Class Operations with Minimum Impact to EnvironmentSpecialists continue to carefully study the survival ability of the trees in the given hot climate and soil salinity. TCO involves contractors who specialize in this area for seasonal and maintenance work, including watering of trees and replacement of seedlings. An inventory of trees taken in spring 2014 shows a fairly high survival rate.

It should be noted that landscaping of Dostyk park was done as part of TCOs Egilik voluntary social infrastructure program, which has a budget of $25 million this year.

Since the project is proving effective, TCO has started landscaping Oilmen’s Alley in Zhana Karaton village of Atyrau Oblast.

– Mr. Guldner, we thank you for the interview.

Published the full text of the article