KIOGE-2014

Well Control Operations with Block Packs as an Efficient Mean to Preserve the Producing Formation Filtration Properties

S.A.Demakhin, A.P.Merkulov, D.N.Kassyanov (Zirax LLC), S.V.Malaiko (Zirax Oilfield Services LLC), D.A.Anfinogentov (IKF-Service CJSC, M-I SWACO, A Schlumberger Company), E.M.Chumakov (M-I SWAC, A Schlumberger Company)

In process of oil, gas and gas-condensate well exploitation, there is a need to ensure the repair works from time to time, which means the need in the well control (capping) operations. When using the traditional blocking liquids (water and salt solutions), their absorption into the reservoir can occur, resulting in the increased volumes of the capping fluid and increase of the relevant work costs. In addition, even a slight absorption of fluid into the reservoir leads to deterioration of the reservoir filtration features and it complicates the well development after the repair.

Absorption of the fluid into the reservoir can be observed during the well capping with various formation pressures, but it is particularly intense in the abnormally low formation pressure (ALFP). Capping such wells is usually associated with special difficulties arising from the considerable absorption of capping liquids by the reservoir. To restore the hydrocarbon inflow from the reservoir requires the additional works on the bottom-hole area, associated with higher costs and longer time line. If there is an intense absorption, the well control with the ordinary liquids becomes impossible, due to the significant increase of saline volume and risk of oil and gas shows. Similar difficulties arise when ensuring the well control in presence of the various formation pressures.

For example, according to article [1], the gas condensate production rates at the Urengoy field declined after the well control operation in the process of overhaul for 60-63%, and the Cenomanian gas wells-for 20 % in average. Each third well required the repeated well control operation due to capping liquid absorption in the highly permeable reservoirs of Cenomanian deposits. The volumes of the absorbed liquid exceeded in 3-4 times the well volumes. The existence of such complications during the well operations justifies the introduction of attenuated well control technologies, aimed at minimizing the loss of fluid in the reservoir.

To solve this problem, the Zirax company, a leading manufacturer and supplier of the well control liquids in Russia and the CIS, together with M-I SWACO (A Schlumberger Company) is holding a project on practical implementation of the special blocking compositions (block packs), allowing to control the fluid absorption into the reservoir. The primary objects for blocking composition use are the wells with abnormally low formation pressure, multi-layered wells, wells with highly permeable reservoirs, integrated well control with relevant works at the underlying layers and the cement squeezes.

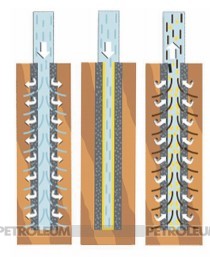

Figure 1. Filtration crust of temporarily blocking composition on the surface of a porous medium

Figure 1. Filtration crust of temporarily blocking composition on the surface of a porous mediumREABLOCK and DIPRO blocking compositions are specially selected system, based on water and salt solution, which allows the well control in a wide range of permeability in a productive horizon due to engineered selection of the sealant fractional composition. The right fractional composition ensures the availability of a dense, thin and impervious filtration crust (~ 0.006 mD) on the well bore surface when creating the repression for reservoir (Fig. 1). The specific feature of filtration crust is the organofilic components, making part of its composition, making it easier for well to reach the operation mode after the repair works, since the crust allows passing the hydrocarbon components of the fluid and it reduces the launch timing.

The sealant fractional composition is chosen individually for each well, using the specially developed software for the optimal calculation of the composition and concentration of OPTIBRIDGE sealant.

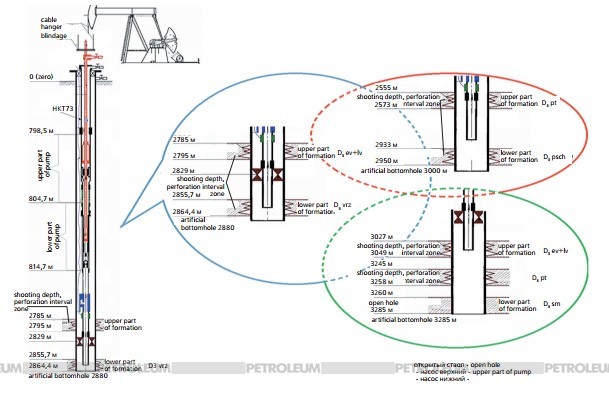

Fig. 2. Block pack operation principle during well capping

Fig. 2. Block pack operation principle during well cappinga) well capping without block-packs results in absorption;

b) well capping with the use of block packs doesn’t result in absorption;

c) a well is put into operation fast and it is quickly reaches the operating mode.

In the process of well control, such a filtration crust is created in the area of the producing reservoir (fig. 2), thereby preventing the deep penetration of the capping liquids into the reservoir. When putting the well into operation, the blocking composition is easily removed from the well at the lowest depression (inflow stimulation) and formation fluids bring it to the surface. To remove the filtration crust, no destroying agents are required, but all the blocking components can be dissolved by the acids.

The filtration crust of blocking composition keeps its properties at least 20 days at temperatures up to 150 0C, which makes it possible to ensure a wide range of works in the wells with different geological and thermal conditions. It should be also noted out that the compositions are fully compatible with all types of reservoir fluids and types of rocks, which was proven in the course of testing, done by the leading Russian research institutes.

REABLOCK composition is primarily designed for the well capping with anomalously low formation pressure, with the use of water and salt solutions. The maximum density is 1.4 g/cm3. Volume of a block pack depends on the well design and the average is 5-10 m3. Well refilling must be ensured with the water-saline solution with required density.

DIPRO system is designed for the well capping in conditions of highly penetrable collectors and anomalously high formation pressure, including the multi-layer formations and it is designed for the use of water and salt solutions with densities, ranging from 1.4 to 1.82 g/cm3 (up to 2.1 g/cm3, if using the zinc-bromide solutions

For DI PRO system, the selection of fractional composition occurs in the same way as for the REABLOCK composition.

Structures are made according to the principle "one bag-one pack", i.e. all components are in the same bag. They packed in 20 and 30 kg bags, depending on the brand of used calcium carbonate. Preparing the block pack does not require any specialized equipment and can be carried out in the field conditions and at lower temperatures. In order to prepare the blocking composition, CA-320 type unit is required, which ensure the mixing process (Figure 3). It is possible to use the water or brines with the required density for the pack mixing.

Figure 3. Blocking composition preparation process

Figure 3. Blocking composition preparation process

All of the above features of REABLOCK and DI PRO allow achieving the following advantages:

- reduced time for preparation;

- simplification and reduction of human factor impact;

- facilitation of logistics;

- no need to use additional equipment;

- no need to involve the solution preparation equipment;

- reduction of transport costs.

It is especially important to use the attenuated blocking compositions for multi-layered well control, including those with the dual completion. Works at such wells sometimes result in the increased complications, especially in the presence of high permeability and considerable differences in the inter-layer reservoir pressure.

Zirax-Oilfield Services has the experience of the successful application of REABLOCK composition for the multi- layered well control in Volgograd region (Figure 4). Capping these wells with ordinary liquids, as well as using the block packs of other manufacturers did not give the desired effect, resulting in an intense absorption, oil and gas shows, need in constant blocking fluid re-fill. Working with REABLOCK led to the successful well capping from the first time and without any problems, which allowed to carry out the necessary repair works and then to complete the works and to put the wells to the operation mode in shortest terms.

Figure 4. Example of the multi-layered wells, being successfully capped with the temporarily blocking REABLOCK composition

Figure 4. Example of the multi-layered wells, being successfully capped with the temporarily blocking REABLOCK composition

Therefore, the well control operations with REABLOCK and DIPRO packs allow to:

- reduce or completely prevent the fluid penetration from the wellbore into the reservoir during the well repair works;

- to keep formation reservoir properties at highest level;

- provide the possibility of secure work in the wells, which previous capping was difficult;

- reduce the well control risks;

- reduce the well development and putting into operation mode in a significant way;

- reduce the cost of a major overhaul.

- reduce the time for preparation of a blocking composition

Well Control Operations with Block Packs as an Efficient Mean to Preserve the Producing Formation Filtration Properties

Well Control Operations with Block Packs as an Efficient Mean to Preserve the Producing Formation Filtration Properties

References

1. Improving the well capping at Urengoy field/V.V. Dmitruk, S.N. Rakhimov, A.A. Boyarkin, E.N. Shtakhov//Oil industry, 2009, # 4, pp. 2-4.

Published the full text of the article