KIOGE-2014

Pump Upgrade Program Helps Local Refineries Lower Total Cost of Ownership

Газизбек Туралиев, региональный директор по продажам, корпорация «Флоусерв»

Газизбек Туралиев, региональный директор по продажам, корпорация «Флоусерв»

About the Flowserve Atyrau QRC

The Flowserve Atyrau Quick Response Centre (QRC) is located in the city of Atyrau, Kazakhstan, within the Atyrau NefteMash LLP engineering plant. It is equipped to provide instantaneous maintenance and repair services to all pumps, mechanical seals and valves used in a variety of markets and industries throughout Central Asia.

With strong engineering support from the Flowserve European Business Units, the Atyrau QRC possesses the capabilities to service, repair and rejuvenate customer equipment to its original or improved operating performance parameters. This is accomplished by carrying out regular service and maintenance and also by applying the latest advances in hydraulic and mechanical design.

Flowserve Corporation is one of the world’s leading providers of fluid motion and control products and services. Operating in facilities around the world, the company produces engineered and industrial pumps, seals and valves as well as a range of related flow management services.

Figure 1. Flowserve QRC in Atyrau, Kazakhstan

Figure 1. Flowserve QRC in Atyrau, Kazakhstan

Introduction

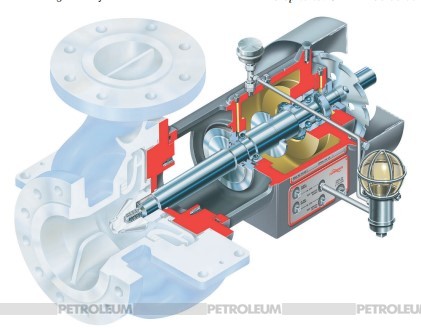

Figure 2. Image of RVX module designed for upgrading API OH2 overhung pump

Figure 2. Image of RVX module designed for upgrading API OH2 overhung pumpAs local refiners follow the industry trend toward facility consolidation, process equipment reliability and efficiency are more important than ever. This is especially true of ISO/API heavy-duty OH2 single-stage process pumps, which are found in significant numbers throughout the typical refinery. When operating to design expectations, these workhorse pumps are the keys to high rates of plant uptime and energy efficiency. The Flowserve Kazakhstan Quick Response Center (QRC) in Atyrau provides its customers with a standardized bearing frame upgrade program to effectively address their needs for improved pump reliability with reduced maintenance costs through increased mean time between repairs (MTBR).

Many refineries continue to use and maintain ISO/API process pumps that were manufactured in the 1950s through the 1970s to long outdated design and performance standards — as far back as API 610 5th Edition. Flowserve has developed the RVX back pull-out assembly upgrade program to provide customers with the advantages of a bearing frame in full compliance with ISO 13709/API 610, latest edition. It also addresses the need to improve hydraulic efficiency or operating stability by replacing existing impellers with new ones specifically selected for current operating modes. The goals: Improved equipment reliability and increased MTBR while reducing total cost of ownership (TCO).