Atyrau Oil & Gas

Post-Drilling Well Development with Use of Flaksokor 110 Acid Solution

S.A. Demakhin, A.P. Merkulov, D.N. Kassyanov (Zirax LLC)

Oil and gas well productivity largely depends on the condition of bottomhole formation zone. One of the important factors influencing its condition is physical and chemical effect of drilling mud in the primary formation drilling.

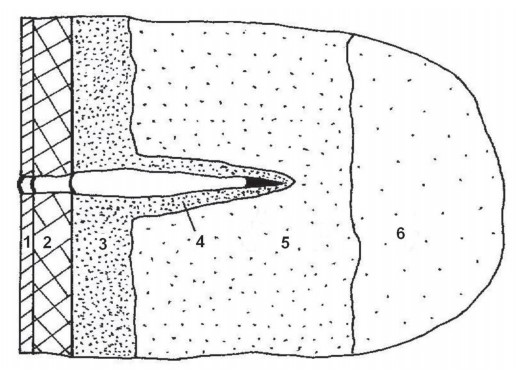

As a result of penetration of drilling fluids in net oil and gas zones, the deterioration of permeability and porosity of the pay zone and the formation of a zone with reduced compared to the native permeability occur. In this case, due to the ingress of the solid phase of the mud into the pore volume of the reservoir, a tight polymer clay cake is formed on the wall of the well (Fig. 1), and liquid phase of the drilling mud with dissolved chemical substances forms an extended zone of penetration, whose permeability is significantly lower compared to the initial permeability (Fig. 2).

Fig. 1. Mud cake formation scheme Fig. 1. Mud cake formation scheme |

Fig. 2. Diagram of the condition of porous medium around the well Fig. 2. Diagram of the condition of porous medium around the well1 - casing 2 - cement sheath 3 - clogging zone (drilling, cementing) 4 - clogging zone (perforation) 5 - flushed zone 6 - zone with native permeability of the reservoir |

In after-drilling well development, to increase the inflow of hydrocarbons into the well and to achieve design indicators of production, it is necessary to ensure an increase in the permeability of the bottomhole formation zone. Wide application of polymers, biopolymers, fillers and weighting materials (barite) in drilling muds complicates the task. Hydrochloric acid baths traditionally used during initial development do not provide complete dissolution of the entire range of contaminants, as hydrochloric acid reacts weakly both with polymers, and clays.

To effectively solve this problem, Zirax LLC, as the producer of a series of acidic solutions [1] offers FLAKSOKOR™ 110 acid solution, whose main task is the destruction of the mud cake and increase of the permeability of the bottomhole formation zone. FLAKSOKOR™ 110 is a ready for use inhibited solution of concentrated hydrochloric acid with a special composition of surfactants and dispersing additives, which allows to:

- quickly and effectively destroy the clogging cake, formed during drilling with the use of polymer-colloid, polymer-clay drilling mud;

- remove the negative impact of drilling mud filtrate on the pay zone;

- to ensure removal of solid colmatants formed in the reaction of FLAKSOKOR 110 with drilling mud and the formation from the bottomhole formation zone.

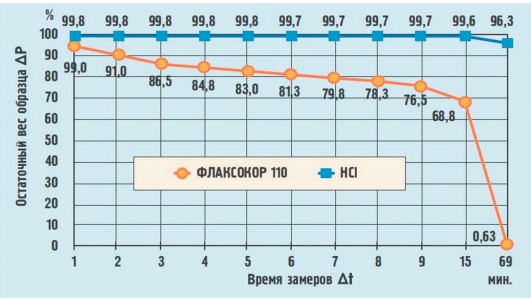

The effectiveness of FLAKSOKOR 110 solution can be seen in Figure 3, which shows the dynamics of destruction of the model sample of clogging cake composed of bentonite clay, barite and polymer, in comparison with the effect of hydrochloric acid [2]. Model sample was almost completely destroyed by FLAKSOKOR 110, whereas the effect of hydrochloric acid is significantly weaker.

Fig. 3. The dynamics of weight decrease of drilling mud cake sample when using FLAKSOKOR 110 in comparison with HCl.

Fig. 3. The dynamics of weight decrease of drilling mud cake sample when using FLAKSOKOR 110 in comparison with HCl.

In 2011, FLAKSOKOR 110 was tested in wells of Astrakhan gas condensate field and showed quite impressive results. Eight development wells were treated, and two jobs were carried out in after-drilling development to clean the bottom and the bore of the well. Treatment of wells using 20-30 m3 of acidic solution resulted in an increase in flow rate by an average of 40%, and additional production exceeded 68 mln m3 of gas-liquid mixture [3]. Since then, the number of wells treated and the purchase of this acid solution have increased.

Since 2012, FLAKSOKOR 110 acid solution has been used for treatment on offshore oil platforms. Lukoil-Nizhnevolzhskneft chose this acid solution after detailed comparative laboratory tests and began to apply it at the oil rig Astra in Yu. Korchagin field in the Caspian Sea.

To date, FLAKSOKOR 110 acid solution proved to be a reliable and efficient acid solution for after-drilling wells development with high efficiency and additional capabilities in comparison with a conventional hydrochloric acid. Its application allows customers to obtain more significant results when using smaller quantities of reagents and to achieve greater economic effect.

References

1. S. A. Demakhin, M. L. Petrushin, A. P. Merkulov, S. V. Malayko “Efficiency of acid solutions from Zirax Company”//Oil and Gas Vertical. - 2012. No.23-24. - p. 10-11.

2. A.I. Mikov, A.I. Shipilov, V. A. Zhuravlev, R. Ye. Zontov "New reagents for wells development after drilling operations, killing the wells by polymer solutions and hydraulic fracturing of formations" / Book of reports of the 5th International Research and Practice Conference on “Modern technologies for carrying out workover operations of the wells and increasing oil recovery of the reservoirs. Development prospects”. Gelendzhik, Krasnodar Territory, 2010. - p. 207-210.

3. L. Nikeshina “Experience of application of Flaksokor 110 filter cake dissolvent and Surfogel diverter for self-diverting acid solution - the result exceeded expectations” //Pulse of Aksarajsk. Weekly Newspaper of GazpromDobycha Astrakhan LLC. - 2012. No.4. Page 1-3

PUBLISHED FULL ARTICLE