Technology

Zirax Group: Quality Oilfield Chemistry – Our Specialty

M. Petrushin, S. Demakhin, A. Merkulov

Zirax now is a group of companies specializing in the oilfield chemicals and includes production, R&D and service companies. Such cooperation helps to realize the full cycle of creating new products and technologies and implementation them to the market (Fig. 1). As a result customers receive the best products and efficient technology for their fields and wells.

Fig. 1. Cycle of creating a new products and technologies in the oilfield chemistry and implementation them to the market

Fig. 1. Cycle of creating a new products and technologies in the oilfield chemistry and implementation them to the market

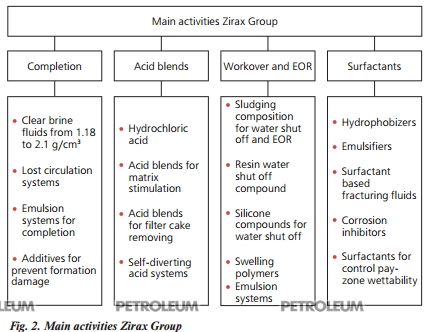

Zirax sells its products and makes service to customers from oil industry in Russia and the CIS, Eastern and Western Europe, North America as well as Africa and the Middle East. The main activities of the companies from Zirax Group are chemicals for completion and killing wells, well stimulation fluids, compositions and technologies for water shut-off and enhanced oil recovery (Fig. 2).

Fig. 2. Main activities Zirax Group

Fig. 2. Main activities Zirax Group

Historically one of the first products in the oilfield chemistry for Zirax was clear brine fluids for completion and killing wells. Currently, we have a wide range of such fluids (Table. 1), which includes high-purity salt of different density, lost circulations systems, emulsion compositions. Wide range of products and technologies for completion and killing wells helps the customer to conduct downhole operations in a variety of geological and technical condi-tions.

Minimizing formation damage in order to save the properties of the reser-voir and especially the near-wellbore zone is one of the important tasks during completion wells. Poor quality completion and killing well may lead to a de-crease in the permeability of the near-wellbore zone up to 10 times or more and dramatically reducing the productivity of the well. To prevent these effects Zirax has own special decisions based on high-purity salts, do not form precipitates in the reservoir, emulsion and lost circu-lation systems, which are not filtered into the reservoir, as well as special addi-tives that reduce the water saturation of the near-wellbore zone and prevent clay swelling and the formation of emulsions. All this provides a "gentle" com-pletion, accelerating and maintaining wells productivity.

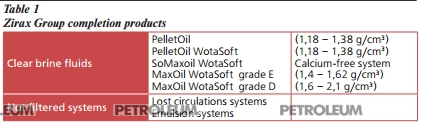

Table 1 Zirax Group completion products

Table 1 Zirax Group completion products

For stimulation Zirax produces acid blends series FLUXOCORETM. They are designed for the intensification well production, and for removing filter cake after drilling, as well as to clean fracture from the residuum polymer gel after fracturing. FLUXOCORE 210TM is a hydrochloric acid-based blend with the addition of surfactants and special additives.

It provides a high penetration ability for acid blend in the formation due to a low interfacial tension at the "acid - oil" and low rate of reaction with the carbonate rock, whereby the acid is able to penetrate deeper into the reservoir. Furthermore, the presence of special additives in the composition can ef-fectively prevent the formation of highly stable emulsions and precipitation. These capabilities allow to use the composition FLUXOCORE 210 TM not only for the standard acid treatment, but also for deep matrix acidizing.

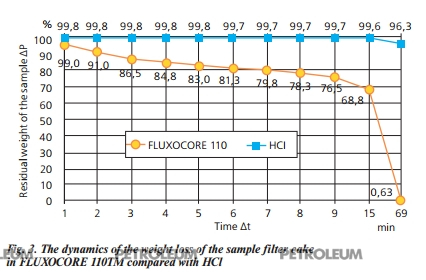

Fig. 3. The dynamics of the weight loss of the sample filter cake in FLUXOCORE 110TM compared with HCl

Fig. 3. The dynamics of the weight loss of the sample filter cake in FLUXOCORE 110TM compared with HCl

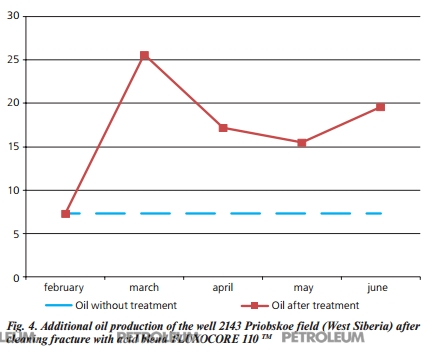

The innovation acid blend is FLUXOCORE 110TM used for removing fil-ter cake after drilling, and cleaning fracture from the residuum polymer gel af-ter fracturing. Composition easily breaks down the filter cake, which is often formed on the surface of the collector (Fig. 3), increases the formation commu-nicability with the well and its productivity. Using such acid blend after frac-turing helps to break down the residuum polymer gel and increases fracture conductivity and productivity of the well. Treatments on the well of the Pri-obskoe field (West Siberia) have allowed to produce additional 1488 tons of oil only for the period 4 months and currently effect continues (Fig. 4).

Fig. 4. Additional oil production of the well 2143 Priobskoe field (West Siberia) after cleaning fracture with acid blend FLUXOCORE 110 TM

Fig. 4. Additional oil production of the well 2143 Priobskoe field (West Siberia) after cleaning fracture with acid blend FLUXOCORE 110 TM

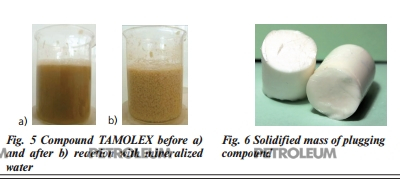

Workover operations, especially in order to reduce water cut and EOR al-so are important sphere of activity for Zirax. Sedimental compound TAMOLEXTM specially designed to decrease water ingression from the collector. Such problems often take place by moving oil-water contact, coning or flooding. This technology is based on the use of sur-factant, which precipitates when mixed with mineralized water (fig. 5). As a re-sult permeable water-saturated intervals is plugged and water filtration re-duced.

The precipitate is dissolved in hydrocarbons, so net pay intervals are not blocked. Also Zirax has shut-off fluids based on urea-formaldehyde resin. These fluids can be used when casing leaks or channel behind casing take place. This resin is a liquid and for this reason have high penetration possibility, so effec-tive when traditional cement solutions can`t be used. After a certain time after mixing with special additives, the resin is cured to form a solid rubbery mass (fig. 6). The composition has been used successfully for the elimination of casing leaks in the high-temperature (130 - 1500C) wells of the Stavropol region (south Russia).

Surfactants for oil production are becoming increasingly broad applica-tion in Zirax. This are hydrophobizers as additives in the killing fluid, surfac-tant acid composition to improve their penetration ability into the formation, emulsifiers for self-diverting acid systems and in the emulsion compositions for killing and water shut-off, corrosion inhibitors and surfactants to control the wettability of the near-wellbore zone.

Zirax priorities are production of surfac-tants and compositions based on them, as well as R&D of new technologies for their effective application in the oil industry. One new technology is fluid for fracturing based on surfactant that increases the conductivity of the proppant pack and thereby increase the effectiveness of fracturing. The cooperation within Zirax Group scientific, industrial and service companies allows to develop and produce the most advanced chemical prod-ucts and provide quality service to our customers.

Published full article