Anniversary

Anniversary Tengiz oil

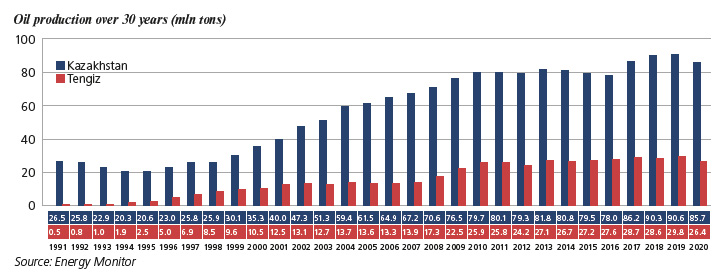

Over 30 years of development, production at the field has increased by 30 times

Thirty years ago, on April 6, 1991, the first well was launched at the unique Tengiz field, which is rightly called the "diamond" in Kazakhstan's oil and gas crown.

"Geological exploration of the eastern side of the Caspian Basin became more active in 1971 when Bulekbay Sagingaliyev became Head of the Embaneft production association (today it is Embamunaigas JSC, a daughter of the national company KazMunayGas), says Laura Suleimenova, Head of the Embamunaigas press-service. – From the first day of his tenure as General Director of Embaneft, Mr. Sagingaliyev set the task for the team: "The oil Emba has not yet said its weighty word. The future of the "old" Emba is in the new pre-salt oil. And we will look for it, despite all the natural and bureaucratic difficulties!".

In May 1976, the Embaneft association received permission to conduct exploratory drilling operations. Three years later, during the testing of the first well, a powerful gush of oil burst out of the ground, putting an end to lengthy disputes: there is oil in Tengiz and huge quantities! Finally, the fate of Tengiz was decided in August 1980, when Bulekbay Sagingaliyev received approval for the development of the Tengiz field personally from Alexei Kosygin, who headed the Council of Ministers of the USSR."

"By April 1991, the complex technological line-1 (CTL-1) was built and passed the full commissioning cycle. A state-of-the-art gas processing plant was built to purify the pre-salt oil from the aggressive components of hydrogen sulfide and mercaptans. For the first time in the domestic oil industry practice, managing the field and the plant in a single cycle was solved in a new way with the help of a specially developed automatic control system based on modern computers. We had almost everything new, and the epithet "for the first time" was quite justifiably applied to everything," recalls Anuarbek Dzhakiyev, former Deputy General Director of the Tengizchevroil joint venture.

The Tengiz gas processing plant was designed by the Soviet research institutes together with the West German Lurgi, built by the Hungarian Vediepser builders, the French Litvin, and the Canadian SNC-Lavalin took part in the infrastructure development of the field. At that time, it became the most modern technological complex of its kind, and the Tengiz construction site the largest object under construction in the country and, possibly, in the world.

On April 6, 1991, at precisely 6 p.m., engineer Boris Vasilyev and operators Abdulkhamit Artygaliyev and Gafur Aubakirov launched the T-8 well. Crude oil was transferred to the factory complex to purify it from hydrogen sulfide and impurities. The launch of the Tengiz oil and gas complex took place. Commercial oil production has begun in Tengiz.

Anuarbek Dzhakiyev, Deputy General Director of TCO (2009-2016), recalls:

"Eyewitnesses tell us that when the first peg was hammered in a festive atmosphere, starting the construction of a gas processing complex in Tengiz, a huge steppe eagle landed on the only trailer in the entire endless steppe. Perhaps, the proud bird thus blessed our large construction site, which soon became a symbol of the Republic of Kazakhstan's economy and high production potential.

Being a direct participant in the commissioning of the Tengiz oil and gas complex, I remember well that momentous day when at 6 p.m. the first well No. 8 was launched, the chain of the oil gathering system of the field was passed, including the group measuring station No. 15, the central field manifold and the slug-catcher, and the first oil finally reached the plant. These were the long-awaited moments of our work and our aspirations. From this moment, the countdown of the oil Tengiz began."

Mukhit Abilgaziyev (in 2008, Head of the group of the Department of Safety, Production Optimization, and Environmental Protection) recalls:

"When Tengiz was discovered, I studied in Moscow, at the Gubkin Institute of Petrochemical and Gas Industry. I had heard a lot about Tengiz and wanted to go there after completing my studies. After graduation, I was sent to the Kulsaryneft OGPO. The OGPO has just created the Tengiz field development preparation group. The first in the group were Anuar Dzhakiyev, Berik Dyusenov, Islam Onalbayev, Boris Vasilyev, Aitkali Uipakov, Malik Tlegenov, Nysanbek Moldiyev, Abdulkhamit Artygaliyev and others who observed the gusher at the 37th well.

I was able to transfer to Tengiz only in October 1986. I began working as an Oil Production Master, then as a Technologist, Production Supervisor. I gained many friends and associates. Many of them are still working in Tengiz. I am sincerely glad to see Zhenis Seitayev, Samat Ismagulov, Kairbek Dzhanasov, Murat Ereshov, Maksot Kerikov, and all of the people mentioned above at every shift check-in. They are all pioneers, and I'm glad to be working with them.

Back in the distant eighties, the conditions were difficult. We lived in trailers, where not only domestic but also steppe mice walked freely. But neither the weak heating in winter nor the lack of air conditioning in the heat could not prevent us from preparing for the development of the field. In 1987, the Tengiz oil field project developed by the Canadian Lafarge Coppee Lavalin was accepted, and its implementation began. The specialists from Lavalin were the first foreigners with whom I had the opportunity to work.

After the successful completion of the oil and gas gathering systems and the plant, the first oil was received on April 6, 1991. For two years, the field operation department developed Tengiz, and the plant refined oil and processed gas. But still, the outdated approaches to the process made themselves felt. The living conditions improved a little, the field mice no longer ran around the housing, but the people's life was not organized at the proper level, there was not enough transport and equipment.

When the joint venture was created, everything changed. First of all, I liked the working methods. The relationship between the manager and subordinates is very friendly, and there was no chaotic resolution of issues. Gradually, the discipline and safety requirements were improved, which have now reached the highest level.

Now it is easy to work, having the latest technology, high-quality equipment, and sufficient funds for their implementation and improvement of production. High technology helps to achieve the goals. The absence of tension in the relations in the team and the increased trust in each other help solve many problems. I have gained a lot of experience in my work, and I am happy to congratulate my colleagues! I wish all TCO employees good health, great success in their work, and well-being to their families!"

Islam Onalbayev, Head of the warehouse management of TCO, recalls:

"I have been working at the Tengiz field since April 6, 1981. Before that, I worked as a workshop supervisor in the Kulsaryneftegas OGPO. Then, by special order of the management of the Embamunaigas production association, the Tengiz production team was created under our supervision.

Nurlan Balgimbayev was appointed Head of the group, and Shambay Urazaliyev, Nurlan Sarkytov, Boris Vasilyev, and Yuri Balduyev were approved as Chief Technologists. If Kenes Baiseitov, Zhalgas Karamanov, Galymzhan Karymbayev and I were assigned the duties of a Senior Technologist, then Kuan Nurmanov, Nysanbek Moldiyev, Abdulkhamit Artygaliyev, Kulbay Tazhenov performed the operator service. This group conducted test work on well No. 1 in the area of the Tengiz field. In June of the same year, instead of Nurlan Balgimbayev, who moved to another job, Bolat Elemanov took the position of Head of the group.

The test work was carried out under the close supervision of the Heads of the Embamunaigas association Bulekbay Sagyngaliyev and Kumar Balzhanov. Unlike other fields, there was more sulfur in the composition of Tengiz oil, so foreign equipment was purchased that could separate sulfur from oil. In particular, the Porto Test unit and Cameron gate valves were delivered from Canada. Thus, the construction of an oil and gas processing plant began at well No. 1 in Tengiz.

The general contractor for the construction was the Embamunaykurylys association, which Ostromensky headed. All oil companies and organizations of the Atyrau region were involved in this work. Enterprises and research institutes of the oil and gas industry of the entire Soviet Union also took part. In September-October, after completing the construction work, we started testing. Our group completely coped with the task assigned to it.

After some time, the Tengiz Oil and Gas Production Department was established based on our group. Bolat Elemanov was appointed Head of the Department, and Kadnen Kudabayev was appointed Chief Engineer. In this enterprise, I worked as a Deputy Head of Supply. In 1991, the construction of the plant and the oil production shop was completed, the plant was put into operation.

The days passed, the months passed, and the year 1993 arrived. And April 6 of that year will forever be inscribed in the history of the Tengiz field. On this day, the leaders of the Republic of Kazakhstan and the Chevron Corporation sign a document on the establishment of a joint venture – Tengizchevroil Limited Liability Partnership. The partnership includes the Tengiz Gas Processing Plant and the Tengiz and Korolevskoye fields. Although then the Korolevskoye was not yet fully explored. And we were joined by foreign specialists, that is, employees of the Chevron Corporation.

New management methods were introduced into production, and the former workers were retrained. In Tengizchevroil, the Production Logistics Department was created, and Mac MacArthur and Paul Kramlich were appointed as its managers. Bolat Mambetov and I were appointed their deputies. Foreign specialists brought a lot of new things to the work. They were also interested in our experience and work methods, used the most necessary things together, improved and developed some things. Then, a little later, because of necessity, a whole warehouse complex was created.

We are proud of our enterprise, which we developed, and where we are working now to benefit our country. It is a great honor for us that our company has achieved great success year after year."

Gabit Bulekenov, the Project Coordinator of the TCO Energy Resources Department, recalls:

"In August 1989, we submitted the documents to the HR Department of the Tengiz Gas Processing Plant. We wrote an application, and we were accepted into workshop No. 3 as technicians of the 4th category of the main gas pipeline. Mikhail Gursky was the Head of the workshop, an excellent specialist, and a mentor.

CTL-1 was still under construction, and there was a two-team method of operation. All the guys who worked here, we knew by sight, constantly communicated with each other. The shift workers then lived in the village of Tengiz. It had its cultural center, shop, and canteen. In the evenings, movies were shown in the village, and a gym was open. A little over a year later, I was appointed master of the Gazoprovod section. And in April 1993, the Tengizchevroil joint venture was formed with its new approaches to the organization and culture of work, with great energy of transformation of production.

TCO was formed when I was very young and just started my career. But we were all sure that with the formation of the joint venture, we would soon become a recognizable company worldwide. Time has proved that we were right. Over the years, much has changed. At the time, the joint venture management, the HR Department, and the Accounting Department were located at the plant. The Trade Union Committee also worked here. When we got settled, CTL-1 was at the completion stage, and CTL-2 was just beginning constructed. The entire Tengiz complex lived in anticipation of the plant's launch. Needless to say, in just a few years, a lot of work was done here, and on April 6, 1991, the CTL-1 was launched.

Later, I had to participate in the launch of СTL-2 and the fifth processing train. For the needs of the settlements of Tengiz, Hungarian village, and the old boiler house of the plant, dry gas was supplied from the village of Kulsary, from the Central Asia - Center main gas pipeline. After the plant's start-up, we delivered gas reverse flow to the CAC line for the first time.

What did TCO give me? I think that it has opened great opportunities for professional growth not only for me but also for all my colleagues. After all, for 15 years, not only the productivity of the oil complex has grown, but also our professionalism. We learned new technologies, new methods of safe operation and put new facilities into operation. We have high requirements for safety and environmental protection and exceptionally high staff capabilities.

Looking back, we can say that much has been done and much more needs to be done in our plant! Much oil, gas, and sulfur have been extracted, and much remains to be extracted!"

Nurzhan Kulbayev, in 2021, Head of the Kazakhstan Chapter of the International Facility Management Association, Houston, USA, recalls:

"The year 1993 is a hungry, cold year. I have already worked in the Tengiz field. It was really hard for everyone, but the Tengiz salary made it possible to live comfortably and even a little better.

The salary was good, but the working conditions were harsh. We took canned food and pasta to the shift, as it was hard to go 15 days on the canteen's meatballs made of rice. Workwear consisted of a quilted jacket and tarpaulin boots. Essential things were missing. I still remember the smell of the inhibitor on my hands since we worked without rubber gloves, sometimes you have lunch, and the scent from your hands overpowers the taste of food.

Dormitories for 3-4 people without air conditioning in 45 degrees of heat. Lack of transport, which is why we drove around the wells on a 50-seat Ikarus bus. We got up at 6 a.m. We were tired, sleep-deprived, hungry, dirty, but young and happy!

Then they came. At that time, for us to see Americans was comparable to seeing Martians in the steppe. The other clothes, the language, the habits, the behavior – all that was new and interesting. I remember our first conversations using phrasebooks: "hello, the dorm is listening…." The first PARTIES, thanks to wine, we already understood and spoke fluently in English. I remember the first salaries in dollars in envelopes delivered on simple field trucks without serious security. White helmets with the Chevron logo, the first PPE, jackets, lace-up shoes that many people wore at home or sold at the bazaar.

And the OFF spray that we were given to fight mosquitoes was a gift from another civilization. If anyone remembers how many mosquitoes were at the wells and MS – it was a nightmare! Toilet paper and Palmolive apple soap that we were handed out, and how we brought them home.

They came, clothed, fed, provided trucks, gave tools and the opportunity to work, motivated, and helped grow and gain knowledge.

Ah, Tengiz is my youth and the best time. Remember – Life is good in the Giz! If it were not for Chevron, Kazakhstan would not have received such a development impulse at that moment. The same plant and field, the same technology, the same people. But they managed to change the style of work, eradicated theft and drunkenness, trained, gave the opportunity to develop, set goals.

For me personally, Chevron has given more than any other institution and changed me for the rest of my life. I still feel the American style within myself, which I learned from my colleagues at Chevron. Thanks to all of them!

Happy birthday, Tengizchevroil!

Nurzhan – TNG field WMD 1993"