Exclusive

KMG EP: Ecology and Modernisation are our Priority

The largest national producing Company of the country - JSC KazMunaiGas Exploration Production (KMG EP) celebrates its 10th anniversary with good financial results: in the first half of 2014, the profit of the Company increased in 5.4 times.

EXPENSES ARE RISING, SO DO THE PROFITS

In August, the Company has published the summary of consolidated interim financial statements, with the net profit for the first six months of 2014 amounted to 210.3 bln KZT (US$1.193 mln), compared to 38.8 bln KZT (US$257 mln) for the same period in 2013. The revenues for the same period amounted to 464.4 bln KZT (US$2,635 mln), which is 21% increase compared to the same period of 2013.

The analysts of Halyk Finance investment Company consider that the net profit increase was supported not only by the foreign exchange gain as a result of the KZT devaluation in February of the current year, but in a greater degree by the smart management decisions, such as increase of crude oil transportation volumes via more commercially viable export routes, tax returns and the strict control over the operating costs.

The international market conditions were also very favourable: the average price of Brent was 1% higher in the first half of 2014 than in the same period of 2013, increasing from US$107.5 per barrel to US$108.9 per barrel. Previously Abat Nurseitov, KMG EP Chief Executive, stated that the Company has a “safety margin” - US$85 per barrel. It allows to upgrade the facilities, to carry on the geological exploration, to follow the production plan and to bring the profits to the shareholders. Production costs in the first six months of 2014 were 88.5 bln KZT (US$502 mln), i.e. 7% increase, compared with the same period of 2013.

MODERNIZATION IS A KEY TO PRODUCTION INCREASE

The Company mainly operates the brown-fields, so keeping the production levels seems to be a challenge. However, even in this conditions KMG EP is successful at increasing the production volumes. So, in the first six months of 2014 the consolidated production of KMG EP amounts to 6.106 thousand tonnes of crude oil, including the shares of JV Kazgermunai LLP (KGM), CCEL (JSC Karazhanbasmunay) and PetroKazakhstan Inc., which is 0.2% higher, compared to the same period of 2013.

All in all, the Company remains committed to its 2014 production plan of 8.170 thousand tonnes for JSC Ozenmunaigas (OMG) and JSC Embamunaigas (EMG). The total production volume of OMG and EMG in the first half of 2014 totalled to 4.018 thousand tonnes, which is 2% higher than in the same period of 2013. At the same time, 2.938 thousand tonnes were exported and 1.010 thousand tonnes were dispatched to the local refineries. Therefore, KMG EP carries out its social mission on providing the domestic market with locally made oil products. Generally, it is expected that OMG and EMG domestic sales will reach 1.9 mln tonnes in 2014.

The Company continues to follow its midrange modernization Programme, launched in 2012, which includes upgrading the infrastructure of the fields, building new production facilities and technology optimisation. Overall investment volume under this Programme for the period from 2012 to 2018 will vary from US$350 mln to US$450 mln. The fulfilment of the Programme will not only allow restoring the oil production rates at the Company’s fields, but also increasing them, and improving the labour conditions for the employees. It is expected that after the full completion of the Programme, the overall production volume from the main assets will increase by 4% in comparison to that of 2013, including the share of Ozenmunaigas, which will rise by 7%, reaching 5.57 mln tonnes.

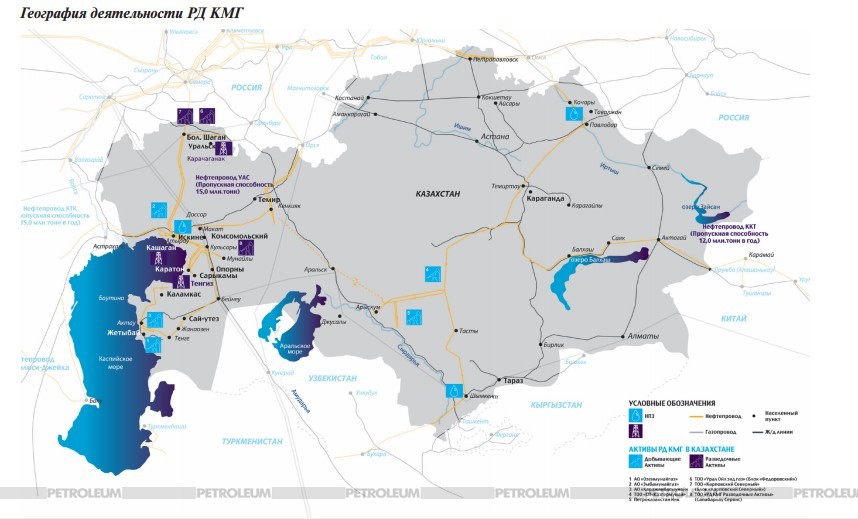

География деятельности РД КМГ

География деятельности РД КМГ

In the first half of 2014, the Company started the pilot production at the Novobogat SE field (above-salt) at Liman block as a part of modernization Programme. Pilot production will take two years and based on the obtained results, a decision will be made regarding the start of commercial production.

Commenting the half-year results, Abat Nurseitov, KMG EP Chief Executive, said: “KMG EP’s results for the first six months of 2014 show that KMG EP continues to accomplish the annual plan. The more manageable and predictable production processes and implementation of the latest technologies for enhanced oil recovery contributed to recover the oil production in Ozenmunaigas. We successfully restored the production process sustainability. Today we invest considerable amount in modernization of our production facilities. We lay the foundation for our Company’s future financial stability.

In January 2012 KMG EP created two service companies: Drilling Well Servicing pision LLP (DWSD) in Zhanaozen and Support Service Vehicles and Well Servicing pision LLP (SSVWSD) in Aktau. 20.6 bln KZT were invested in their development; more than 300 units of new special-purpose machinery were bought. The development strategy of this two companies suggests that they will render services not only for KMG EP, but also to other producing companies in the region.

In the first half of 2014, DWSD performed well servicing operations on 1.537 wells and work-over operations on 27 wells. Work-over and well servicing operations on 50 and 2.928 wells respectively are scheduled for 2014. In the first half of 2014, SSVWSD performed work-overs on 21 wells and well servicing operations on 390 wells. It is planned to perform work-overs on 45 wells and well servicing operations on 760 wells in 2014. During the second half of 2013, two service bases were put into operation at SSVWSD.

The expansion projects for these service bases were completed in the first half of 2014 and the new facilities were commissioned within the frameworks of this projects. Specifically, the service base at Kalamkas field has been expanded to accommodate repair and storage of 100 motor vehicles and special equipment for work-over operations. At Karazhanbas field, the service base has been expanded to enable repair and storage of 250 motor vehicles and special equipment for work-over operations.

EMG completed the construction of gas utilization plant at S. Balgimbayev field in August 2013. The facility with designed capacity of 20 mln cubic meters per year, will prevent associated gas flaring in accordance with the environmental legislation requirements. The sum of 1.4 bln KZT (US$9.6mln) has been invested in the construction of this gas utilization unit. Part of the processed gas will be used for the Company’s own needs. The remainder will be sold to the domestic market at a price set by the government. Starting from June 2014 the gas utilization unit is running in a test mode. The unit is expected to be put into full operation in 4Q2014.