Geology

Recovery of residual oil from mature fields

S.S. BEISEKOV, General Director of

The article presents rationale project on redevelopment of mature suspended fields Shubarkudyk and Zhaksymai, and recovery of difficult to recover residual oil.

Depletion of medium and light oil reserves makes oil industry pay more and more attention to commercial development of heavy, high viscosity oil difficult to recover. Production, processing and transportation of such oil involve difficulties and sometimes become impossible due to its low mobility caused by high viscosity.

Scope of researches on development of high viscosity oil expands. Light oil is recovered for up to 50%, heavy high viscosity oil – from 10% to 30%, depending on oil, water and reservoir characteristics.

Decrease of oil production is expected in the nearest future at oil and gas fields of the world that have been developed for a long time. And this happens amid decrease of reserves renewal due to discovery of new fields. Therefore and considering increase of energy consumption, oil recovery ratio needs to be increased at fields under development and new fields and suspended light and heavy oil reservoirs need to be developed. By estimates of International Energy Agency global demand for primary energy resources (base case) will be increasing at average for 1.5% per year, and to 2030 it will increase for almost 40% if compared with 2007, when all time high consumption of fuel and energy resources was reached [12].

It is impossible to understand and certainly to create new principles and technologies for high viscosity oil fields development without thorough study of reservoir engineering, underground gas- and hydrodynamics, theory of natural hydrocarbons fields development, methods of optimisation theory, numerical analysis, technologies proof-run at polygon and conformity with ethics. Informal comprehension of these disciplines is achieved not only by reading textbooks, technical literature but also by continuous study of advanced science innovations and advanced experience which are though rarely but published. Otherwise one will have to reinvent already invented things and be behind others in creation and introduction of innovations.

"Project on redevelopment of mature suspended fields Shubarkudyk and Zhaksymai" - the first in RoK oil industry industrial and innovation project, which is focused on recovery of residual reserves difficult to recover, was developed in "KANTAR Oil" LLP and submitted to Ministry of Oil and Gas in early 2012 and is still pending. Thus there are no new advanced researches for production of difficult to recover oil, including residual oil from suspended fields.

Oil reserves left after oil field development can be included into oil residual reserves category. The main reasons for residual oil are [15]:

- geological complexity, caused by macroheterogeneity of formations (lenses, sand-to-shale and discontinuity characteristics of formations);

- oil viscosity is greater then water viscosity;

- presence of water and oil zone;

- residual oil saturation in watered formations in the form of film or drip oil and other

Prevailing type of residual oil largely defines choice of methods for its recovery.

Difficult for recovery reserves are:

- in watered formations (residual oil);

- in low permeability reservoirs, as well as high viscosity oil;

- in deep-lying formations;

- in under gas cap zones, water-gas reservoirs and reservoirs with bottom water and high viscosity oil.

Anyway all the above mentioned categories do not clearly define reserves difficult to recover.

Shubarkudyk and Zhaksymai fields are suspended. Many wells are depressurised, there are oil puddles at many wellhead areas and gas comes out into the atmosphere through downhole oil. Oil density under reservoir conditions depends on amount of dissolved gas, temperature and pressure [2]. Increase of dissolved gas temperature and quantity decreases oil density and viscosity.

It is reasonable for us in Kazakhstan to create our own technologies for development of deposits with difficult to recover resources, rather then use the ones created by others at other continents trying to adapt them to use in our conditions. As creative activity brings joy to the creator and people around him.

Global energy situation is such that energy demand must double by 2050. At the same time increase of readily available oil production can hardly keep up with the demand even today. It is expected that peak of conventional light oil production rate will be reached in 10-15 years already, and later on their production rate will be decreasing [3]. That is why oil industry needs to pay more and more attention to heavy oil and asphalt today.

Residual oil reserves of Shubarkudyk and Zhaksymai fields are at the stage of oil transfer into asphalt due to degassing (gas escape into atmosphere through unsealed wells).

There are the following natural liquid hydrocarbons: of low viscosity (0.4-10 mPa∙s), of medium viscosity (10-50 mPa∙s), of high viscosity (50-1500 mPa∙s), heavy (over 1500 mPa∙s) oil and asphalts (over (20-25)103 mPa∙s). Oil reserves of more than 50 mPa∙s viscosity are commonly referred to as difficult to recover reserves [4].

Current design and actual average oil recovery ratio for active reserves is 38-45%, for low permeability reservoirs - 10-35%, and for high viscosity oil - 5-25% [5].

Increase of development efficiency for fields with difficult to recover reserves, is first of all connected with creating of efficient technologies for extraction of difficult to recover oil and introduction of advanced technologies with our own technologies among them considering conditions of suspended oil fields.

Shubarkudyk field, discovered in 1931, is located in Temir region of Aktobe oblast. It is confined to salt-dome structure. The deposit shape is complex due to reservoirs zoning. With total thickness of 50 m net oil pay of poorly consolidated sandstones is 5.89 m, their porosity is up to 27%, permeability is 0.27 micron2,oil saturation ration is 0.7. Initial (1931) reservoir pressure was 3.5 MPa. Initial (1931) oil production rates were 6.6 m3 per day, oil density 910 kg/m3, sulphur content 0.6%, parrafine content 1.5% with melting temperature of 55 0С, resin and asphaltene 53.1%. Kinematic viscosity was 64.6 cSt, flash point 17-49 0С, pour point below – 20 0С. Bubble point was 82 0С with yield up to 200 0С - 12.84% and up to 300 0С – 22.73% [7]. Formation water is of sodium sulphate type, with density of 1,061 kg/м3, with traces of iodine, bromine. The field has been suspended since 1973 after 42 years of development due to complete depletion of recoverable reserves at that time.

Zhaksymai field, discovered in 1933, is confined to three wing salt-dome structure. Pay zone of poorly defined permian-triassic and lias systems are represented by terrigenous rock. Formation depth is 330-380 m, traps are tectonic and screened. Porosity is – 24.9-33.4%, permeability is 0.03-0.08 micron2, oil saturation ratio is 0.73-0.79. With total thickness of 35-45 m, net thickness is 9-12 m, net oil pay is 7.5-8.5 м, initial (1933) formation pressure in permian-triassic deposit was 5.5 MPa, in lias 3.5 MPa. Production rates were up to 5.9 m3/day, oil density – 849-904 kg/m3. Sulphur content was – 0.29-0.4%, paraffin – 0.17-0.84%, resin and asphaltene – 12-20%. Kinematic viscosity was – 14.5 cSt at 200С, flash point – 90С, pour point below – 30 0С, bubble point 51-69 0С with yield up to 100 0С – 3.1%, up to 200 0С – 20.63% and up to 300 0С – 43.18% [7]. There is sodium bicarbonate type water in lias with density of 1,036 kg/m3, and calcium chloride water in triassic with density of 1,086 kg/m3. After 42 years of development water cut was over 85% (87%) and since 1975 the field has been suspended due to complete depletion of recoverable reserves.

It is necessary to be creative in creation of techniques for development of reserves difficult to recover, and first of all to introduce innovations at mature oil fields Shubarkudyk and Zhaksymai– but currently due to delays in subsoil use formalities for the first and only applicant "KANTAR OiL" LLP and spontaneous escape of light oil fractions and gas from abandoned well heads, these fields can create "man-caused" emergency situation for nearby communities having the same names as the mentioned fields.

Crude hydrocarbons market involves forced fluid withdrawal. Uncontrolled withdrawal and neglect of porosity and permeability system causes early creation of difficult to recover hydrocarbons and high oil recovery ratios from pay zones of developed fields are not reached.

Consequently quality of residual reserves deteriorates due to intense development of good active reserves. Active reserves can be developed for 50% and up to 75% and reserves difficult to recover can be developed for only 20%, with maximum - up to 35% [10].

Scientific researches results [1] have shown advisability of development of water-oil zones and water floating oil with systems of horizontal wells. Horizontal wells are distinguished with evident advantage if compared with vertical wells both by oil production rates and accumulative amounts of recoverable oil. If current oil recovery index for vertical wells is 5.5-8.0%, it is within 28-33% for horizontal wells, so there is several fold difference. The mentioned ranges of values depend on well nodes sizes. With increase of well nodes sizes such development indicators as initial well oil recovery rates, accumulated amounts of oil recovered and oil recovery indexes increase correspondingly. It has been noted that sizes of nodes approximating with horizontal hole in X-axis direction are not critical as they do not form pike-shaped pressure sink.

Physical explanation of these results is as follows. When vertical wells are used and well nodes size is 1x1 m, well production rate is spread within 1x1 area. For well nodes sizes 50x50 m production rate is spread over much bigger area [1]. As a result pressure sink nearby well node is not so great and that is why coning kinetics is less dynamic with all the ensuing consequences. If wells are required to be replaced due to their inefficiency, new wells at Shubarkudyk and Zhaksymai fields will be horizontal. Wells drilling, workover and development will be done at drawdown with foam systems applied.

The scientists in their researches have also proposed new well operation method - predetermined water cut method. In other words, waterflooding rates are not unpredictable results of tasks solution, but a limit for watercut of product. Provided that formation pressure remains unchanged predetermined product watercut is kept by reduction of reservoir drawdown. New technological method of predetermined watercut is characterized by well-defined current and final quantitative indicators that facilitates further technical and economic estimations and selection of the best way to develop water and oil zones or oil reservoirs with bottom water, as well as design of field facilities.

According to field researches [1] vertical hole brings oil recovery index to 3% for 10 years of oil and water reservoir element operation, introduction of a horizontal hole since the 11th year will allow to reach oil recovery index of 23%.

It must be noted that poorly consolidated rocks of production reservoirs in some viscous oil reservoirs make use of horizontal wells difficult. During operation of wells with poorly consolidated rocks oil is recovered together with sand that causes failure of pipes and equipment by plugs and abrasion. Increase of sand recovery lowers oil recovery index to minimum.

Sand increases stability of oil emulsion that makes water and oil separation at processing facilities more difficult.

Intense extraction is unfeasible for sand wells. Fluid extraction from sand wells, is defined by the following formula depending on specific conditions and capacities available, for given pipe and rods sizes [6]:

|

σ, %

|

0.1-0.5

|

0.5-1.0

|

1.0-3.0

|

3.0-4.0

|

|

k

|

0.4

|

0.35

|

0.30

|

0.25

|

where Qmin – minimum production rate, that ensures adequate sand recovery; k – this parameter value is taken from flowrate sand concentration table σ, %;

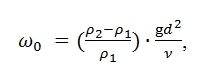

ω0– sand gravity settling rate, is defined by Stokes' formula:

where ρ2, ρ1 – are respectively density of sand grains and liquid; d – sand grains diameter; ν – kinematic viscosity of liquid; F – inner width of the pipe filled with sand liquid.

If production rate is equal to Qmin – the task is considered solved.

Recently artificial filters from highly-permeable grouting rocks with portland cement, filler with open porosity pre-filled with formation water or light oil are created in bottomhole zone of wells in loose poorly consolidated reservoir-rocks [6]. Bottomhole zone filter - grouting rocks of porosity ensuring oil recovery with minimum sand content.

Reservoirs and fluids conditions determine wells development system, wells production rates, completeness of oil recovery, collection processes and other. Oil production techniques are much influenced by sand entry from reservoir into wellbore, paraffin deposition and precipitation, deposits of mineral salts, corrosive characteristics of fluids and other.

Permeability together with formation thickness and oil viscosity define well production rate [8].

Wells of viscous oil reservoirs cannot be extra-high rate wells, they are always low-rate ones.

It must be noted that methane, ethane and other hydrocarbon gases are also dissolved in viscous oil under reservoir conditions with gas ratio about 10 m3/t. Pressure in many depressurised wells of Shubarkudyk and Zhaksymai fields has dropped below saturation pressure as a result of methane, ethane and other hydrocarbon gases escape, structural and mechanical properties of oil improve, that is why degassing of abnormal oil in reservoir is unacceptable [8].

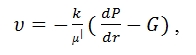

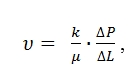

Permeability rate of oil with structural and mechanical properties in porous medium is calculated by formula [2]:

Permeability rate of conventional oil in porous medium is calculated by formula [2]:

where ![]() – linear filtration rate; k – permeability ratio; μ – dynamic viscosity of conventional oil;

– linear filtration rate; k – permeability ratio; μ – dynamic viscosity of conventional oil; ![]() – viscosity of oil with structural and mechanical properties; ∆P – differential pressure between two points in sample at distance L in direction of fluid flow (oil); dP/dr – pressure gradient in asymmetrical coordinate system; G – initial, limit pressure gradient.

– viscosity of oil with structural and mechanical properties; ∆P – differential pressure between two points in sample at distance L in direction of fluid flow (oil); dP/dr – pressure gradient in asymmetrical coordinate system; G – initial, limit pressure gradient.

Using the above formulas it can be found that flow of oil with structural and mechanical properties (viscous oil) hrough porous medium is several times lower, and production rate is several times lower accordingly.

Oil with structural and mechanical properties - viscoplastic fluid - starts moving when limit gradient is exceeded (G). The following basic and innovative technologies [13] can be used to destruct such structured oil that will produce viscosity reduction effect:

1. Addition of oil-soluble surfactants and polymers;

2. Heat treatment;

3. Addition of not expensive solvents, for example wastes and by-products of oil processing and petrochemicals;

4. Ultrasonic treatment or its combination with chemicals (combination of technologies).

Efficiency of each of the above mentioned technological approaches must define further field and scientific research activities.

Petrakov's cavitation machine is used to decrease viscosity and as a result increase mobility [14].

Currently, when exploration of recoverable oil is far behind oil production it is particularly necessary to make oil recovery more complete for the recovered oil to be 1.5-2 times more with the same amounts of oil in place. According to academician V.D. Lysenko it can be achieved by alternate injection of water and small part of oil recovered [11].

During viscous oil recovery water breakthrough and product water cut can be met more often due to big difference in mobility, to be more exact, in viscosity. Moreover, difference between vertical and horizontal permeability in viscous oil reservoirs is often much lower, that causes water coning and increase of well product water cut. And here the main forces are viscous and gravity ones.

Viscous forces are connected with force of friction between fluid phases at interface. They are counterbalanced by Archimedes' buoyancy force caused by difference in oil and water density. Stable water cone appears at low drawdown and a well can operate for a long time without water breakthrough.

This operation condition is called subcritical. With increase of drawdown oil-water contact (OWC) surface around well bore increases and reaches perforation level and as a result involves water breakthrough. Critical drawdoan is defined by correlation [9]:

where ![]() – difference in oil and water density;

– difference in oil and water density; ![]() – distance from wellbore to OWC level. For example, for Shubarkudyk field, at

– distance from wellbore to OWC level. For example, for Shubarkudyk field, at ![]() = 910 kg/m3,

= 910 kg/m3, ![]() = 1,061 kg/m3, g = 9.81,

= 1,061 kg/m3, g = 9.81, ![]() = 15 m, ∆ρ = (1,061-910)∙9.81∙15 = 22,219.65 Pa = 0.02221965 MPa ≈ 0.22 atm. Critical drawdown value is usually low and oil production rate will be low.

= 15 m, ∆ρ = (1,061-910)∙9.81∙15 = 22,219.65 Pa = 0.02221965 MPa ≈ 0.22 atm. Critical drawdown value is usually low and oil production rate will be low.

Scientists propose to introduce DOUBLE TAIL technology for intense development of viscous oil reservoirs, which is based on simultaneous extraction of water and oil with two horizontal wells. Parallel water and oil movement to production well bottom holes ensures uniform recovery of resources not limited to critical drawdown.

The following is noted in monograph [7]: "Only new solutions of action on bottom-hole area and reservoir can facilitate recovery of residual oil from mature fields".

It is also proposed to test and introduce binary mixtures technology and various types of wave action on bottom-hole area and reservoir at Shubarkudyk and Zhaksymai fields.

All recent developments introduced and applied at Shubarkudyk and Zhaksymai fields, methodical and technological ideas will be comprehended, field tested and they will become RoK domain [7]. In this regard it would be reasonable to make Shubarkudyk and Zhaksymai fields sites for development of difficult to recover reserves from the very beginning.

Global average oil recovery is – 30%; average oil recovery for USA fields – 39%; estimation of actual oil recovery in future – 50-60% (OGY, No.12, 2007.) [10]; average design oil recovery for Russia fields – 38% (as per data published by State Reserves Committee of the Russian Federation); average design oil recovery for Kazakhstan oil fields – (from estimated sources) does not reach 30%, as there is no supporting information published.

Additional production by means of "tertiary" methods for recovery enhancement: globally – 120-130 mln t/year; in USA – 34.4 mln t/year; in Russia – a little higher than 1.5 mln t/year [10]; in Kazakhstan (by estimation data) – approximately from 0.25 to 0.5 mln t/year, as there is no supporting information published.

Academician Renat Muslimov, following quotation of I.M. Gubkin: "We have poor knowledge of our rich reserves", thoroughly studied hydrocarbon deposits and made the conclusion: "The planet will face complete depletion of hydrocarbons neither in the short nor in the long term, the meanest field will operate for at least a hundred years". It turns out that due to high rate of global geochemical cycle of substances typical period for oil and gas accumulation in modern age is about 260 years [1]. Hence it appears that intense use of subsoil resources can help people to eliminate or mitigate energy resources problem. According to new notions, resulting from researches of A.A. Barenbaum with "space help" hydrocarbon resources in reservoirs are largely renewable. Oxidized carbon in combustion products is involved back into glogal geochemical cycle. Being renewed in the cycle this carbon feeds oil and gas fields under development and newly accumulated ones [1].

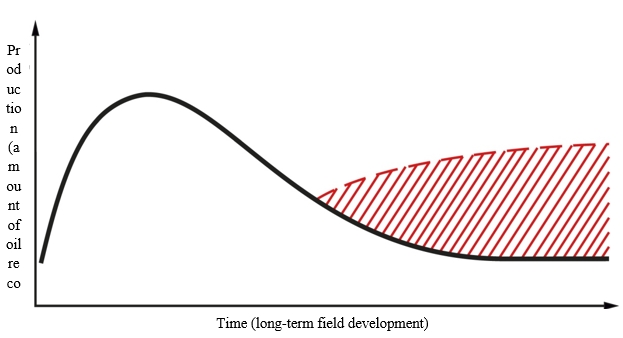

According to convictions of academician Renat Muslimov on possible long term operation of the "meanest" oil fields there are author's notes and conventional graphical proposal as follows: to prevent oil fields development till their complete (significant depletion) and also prevent water cut of these fields reaching unacceptable limits of 86% and 87%, and in cases when steady decrease of conventional recoverable oil production rate is found to start early activities on additional increase of recoverable reserves by development and production of reserves difficult to recover which usually remain in-situ in amount of up to 70%. See chart:

Figure 1 - Oil fields production (development) chart with early additional in-crease of reserves by recovery of residual oil reserves difficult to recover

Figure 1 - Oil fields production (development) chart with early additional in-crease of reserves by recovery of residual oil reserves difficult to recover

Currently less than a half of conventional oil is being recovered, as for viscous oil - less than 30%, important inferences come out of galactocentric paradigm for theory and practice of oil and gas fields development, conclusion is made that oil and/or gas in place is not a concept [1]. Input of natural hydrocarbons into developed or suspended oil and gas fields hence they need to be re-developed.

References:

1. Zakirov S.N., Zakirov E.S., Zakirov I.S., Baganova M.N., Spiridov A.V. New principles and techniques of oil and gas fields development. М: year 2004, pages 34, 116, 158, 175-176, 192-206.

2. Abdulin F.S. Oil and gas production. М.: Nedra, year 1983, pages 9, 22-25.

3. Schepalov A.A. Heavy oil, gas hydrates and other prospective sources of crude hydrocarbons. Nizhny Novgorod, 2012, page 6.

4. Surguchev M.L. Secondary and tertiary methods for enhanced oil recovery. М.: Nedra, year 1985, pages 17, 107.

5. Khavkin A.Ya. Nanotechnologies in oil and gas production. М: year 2008, page 13.

6. Pirverdyan A.M. Protection of downhole pump from gas and sand. М.: Nedra, year 1986, pages 6, 20.

7. Beisekov S.S. Secondary development of oil fields. Aktobe, year 2014, pages 7, 14-15, 302, 338.

8. Boiko V.S. Development and operation of oil fields. М.: Nedra, year 1990, pages 97, 368-376.

9. Khokhlov D.I., Popov I.P. Enchancement of reservoir development efficiency at  Novo-Purpeiskoye field by introduction of DOUBLETAIL technology as a method for prevention of bottom water coning. Petroleum engineering, 9/2014, page 24.

Novo-Purpeiskoye field by introduction of DOUBLETAIL technology as a method for prevention of bottom water coning. Petroleum engineering, 9/2014, page 24.

10. Kryanev D.Yu., Zhdanov S.A. Scientific support for new technologies of development of oil fields with difficult to recover reserves. Drilling and oil, 2012, No.08, pages 29-32.

11. Lysenko V.D. Enhanced oil recovery at high viscosity oil fields. Petroleum engineering, 10/2006, page 6.

12. Sakharov A.A. Liquefied natural gas, current state and intrinsic development trends. Petroleum engineering, 9/2011, page 49.

13. Dmitriyeva A.Yu., Musabirov M.Kh., Shashina V.D. and others High viscosity oil microstructure analysis. Equipment and technologies for oil and gas sector, 5/2014, page 19.

14. Dudkin D.V., Yakubenko A.A., Novikov A.A. and others Changes in chemical composition of residual oil under hydrodynamic cavitation action. Oil and gas technologies, 5/2013, page 3.

15. Nazarova L.N. Development of oil and gas fields with difficult to recover reserves. М.: Gubkin Russian state oil and gas university 2011, pages 4-9.

Published the full text of the article