30 years of TCO in Kazakhstan

TCO Digital Transformation: From Bytes to Barrels

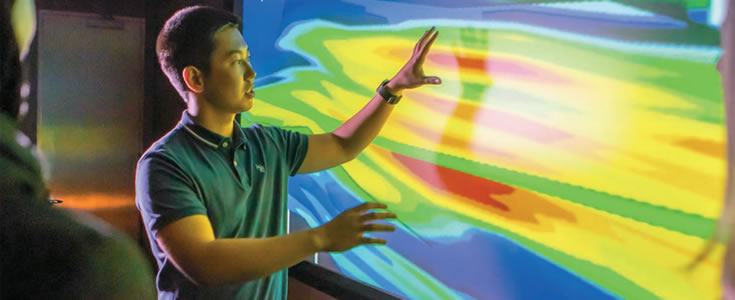

Digital transformation in operations is much more than just the introduction of advanced technologies. It involves building a new digital culture which enables safe execution of work, continued increase of productivity and adds value throughout the value chain. Tengizchevroil adheres to this principle which allows the company to demonstrate remarkable performance.

The Key to Efficiency

TCO started digitalizing its business processes before digital transformation spread widely. The company has been introducing state-of-the-art technologies at all facilities over the course of its history given the scale of Tengiz and Korolev fields and process challenges associated with the development of giant and deep fields. Building a digital culture began with rolling out computer trainings for all personnel to to provide them with required skills and knowledge. Early implementation of digital technology improved communication among employees & allowed experts to quickly and effectively share data and expertise.

The number of digital solutions that helped optimize processes and save time increased every year. 2020 COVID-19 pandemic contributed to accelerated digitalization. Ensuring health and safety of personnel and safe working conditions have always been and remain the company's main priority.

After the pandemic had been announced in the country, the company in just a few weeks created and implemented new workflows and tools that helped the team to prevent the spread of the infection. Digital tools enabled detection of potential outbreaks at an early stage and take timely actions to isolate infected personnel or a rotational camp. Digital dashboards were used to track personnel on rotation, beds in hospitals and medical centers, daily incidence rate, testing and isolation data, and other indicators that gave a clear picture of the situation on site and helped management make the right decisions that ensure health and safety of personnel and maintain current production levels.

The Life and Safety of Pesonnel are a Priority

Digital transformation, like any other TCO initiative, is implemented with a continued focus on safe operations, personnel safety, process safety and environment protection. The company prioritizes initiatives and digital products that increase the safety of employees and operations and reduce carbon footprint. One of the first digital products implemented in Tengizchevroil was an Intelligent Vehicle Safety Project. All vehicles operated by the company and a contractor were equipped with a fatigue recognition system. The system signals if it detects that a driver has the signs of fatigue and drowsiness. This helped reduce motor vehicle incidents in the field significantly.

TCO became the first company in the oil and gas sector of Kazakhstan that transitioned to a digital permit to work systrem. It was a staged transition that started in late 2019. The main benefits of the electronic permit to work system are process optimization, production efficiency, and, above all, health and safety of personnel. Employees can log in to the system using any smartphone or a tablet connected to the Internet and approve permits at the workplace immediately after conducting an inspection. "We feel proud to see how digital technologies ensure safe and reliable operation and prevent incidents throughout the value chain. SGP and KTL turnarounds in 2021-2022 were successfully executed with several digital improvements, such as electronic permit to work, electric pre-start up safety review, and digital solutions for an integrated operations control center, increased mobility due to deployed private LTE network, industrial Wi-FI network and LoRaWAN Internet of Things network. All these initiatives enable an immediate access to available data at the production facility, ensure a clear understanding of safety requirements and make sure that safeguards are in place and functioning before starting the work," commented Marat Kuatov, TCO Digitalization Champion. Kevin Lyon, Tengizchevroil General Director, presented these and many other digital achievements to the President of the Republic of Kazakhstan Kassym-Jomart Tokayev, at 2021 Digital Bridge Forum in Astana.

Digitalization Enabled Revenue Increase

Another challenge for the company and oil and gas industry as a whole was drop in prices for hydrocarbons, followed by production curtailment & restrictions under OPEC+ agreement. In response to these challenges, TCO established cross-functional teams to identify ways to optimize revenue in the changed conditions.

In the same year, 2020, liquefied petroleum gas (LPG) production was increased at the Complex Technological Line (KTL) using a Virtual Plant solution, which combined instrumentation data of the entire plant in real-time. Feed to the Gas Processing Plant was increased at the Second Generation Plant using a DMC+ controller. This technology is designed to maximize butane content in crude.

LPG production increase in Tengiz using digital technologies helped compensate for the consequences of OPEC+ production restrictions and allowed the company to optimize the value chain through digital solutions and rapid response to changing conditions.

FGP-WPMP in Alternate Reality

Future Growth Project-Wellhead Pressure Management Project (FGP-WPMP) is one of the company's largest and most important projects in 30 years of operation in Tengiz. This is the largest and most significant capital project not only in Kazakhstan, but also in oil and gas industry globally. TCO faced new challenges such as planning, engineering solutions, and logistics.

The company used a SWIFT digital solution to ensure the execution of required work at the right time. SWIFT is an integrated software used to forecast systems completion and work planning which enabled more effective management of FGP-WPMP critical path.

SWIFT continuously improves decision-making process for integrated project teams, helping them prepare and execute work efficiently. It also allows to verify the completion of a task before proceeding to new activities. This software tracks the closure of project documentation so that teams could access commissioning information at any time.

SWIFT visualizes the completion of construction activities in real time by integrating information from over ten systems and coordinating thousands of an individual set of installation work, helping ensure an efficient and effective transition from mass construction to consistent planning of construction work. An integrated holistic view on the status of construction and systems completion at the activity level provides an excellent opportunity to quickly respond to changes in operating conditions, identify risks and apply appropriate mitigation measures at the right time.

Hololens goggles is another digital solution that proved effective at the FGP-WPMP. It is an ergonomic, wireless, stand-alone holographic device with corporate applications manufactured by Microsoft. It increases the accuracy and efficiency of user's performance. It allows focusing on safe, faultless execution of tasks by tracking hand and eye movements, built-in voice commands, spatial mapping and a large viewing area. An employee wearing Hololens goggles can track hand movements, touch and move holograms, share these holograms with colleagues located in different parts of the world, and share information using photos and videos created in real time through mixed reality recording.

TCO developed an application that employees can use to share their ideas on simplifying and reducing routine tasks. Ideas received are reviewed by Digital Department that finds ways to solve the problem. Digital Champion approves the project for further implementation after evaluating operational needs and product profitability based on its cost.

Successful digitalization at such a complex facility as Tengiz is primarily driven by the fact that the initiative comes from the operations and employees, not from senior leadership. Digitalization in Tengizchevroil is implemented not just to follow trend, but to optimize operational tasks and deliver specific, measurable results. Each digital product or initiative must be competitive and have a direct impact on the company's key metrics and goals.

People Are the Main Asset

People are the main component of TCO digital transformation. Developing their digital competencies and skills is a crucial factor of success. Therefore, an integral part of TCO digitalization program is an investment in human capital, training of Kazakhstani employees, partnership with Kazakhstani and foreign universities, local IT hubs, and the involvement of Kazakhstani IT companies to introduce digital products in TCO’s business.

The company's innovative know-how is an annual Digital Yurt, where employees train, develop and apply skills during an internal Hackathon designed to solve real business problems. The topic of 2020 Digital Yurt was ‘Artificial Intelligence and Computer Training.’ Fifty TCO employees took courses on Big Data, obtained skills and tools to apply them effectively. The participants received a real business problem and a corresponding data set for the Hackathon. They were also given 6 hours to complete the full cycle of Big Data project development, including presenting their recommendations to a jury consisting of TCO experts. Over 210 employees have become digital pioneers, shared their innovative ideas with trainers, and were able to develop solutions for the needs of their departments since the program rolled out. In addition, in 2022, TCO held three successful Hackathons on PowerBI, PowerApps, and Robotic Process Automation, attended by more than 60 participants from all over the company. These initiatives proved that any employee, regardless of their training or background, can connect to the TCO digital ecosystem, improve digital technology skills and create technological solutions to solve business problems, creating value for TCO.

In June 2022, the first open Digital Tengizchevroil-2022 Hackathon took place in Almaty, attended by 30 teams of developers from all regions of Kazakhstan. The announced goal of the event was to find new companies capable of developing unique digital products. Thus, the company plans to expand the list of Kazakhstani IT service providers. The three winning teams that found the best solution to the problem were given the opportunity to sign a six-month contract with TCO.

‘This was the first open Hackathon under digitalization events organized by TCO among Kazakhstani IT companies. Despite the tight deadlines, a lot of companies expressed their interest and were able to demonstrate their capabilities and best practices for solving a given case. This is a big step for the development of cooperation between the largest companies, such as TCO, and the domestic IT sector. We hope that other major companies will follow our example and actively involve the local market for digital solutions. During the Forum and Hackathon, we were convinced that we had competitive companies that could represent Kazakhstan both locally and internationally,’ commented Klara Zholdasbayeva, TCO SCM Business Manager and a member of the Hackathon jury.

The company has been implementing a Digital Scholar Program for several years now. It is designed to prepare Kazakhstani leaders for the future of digital innovation. Local TCO employees enroll at Rice University and the Massachusetts Institute of Technology for a one-year master's program in engineering, management and digital technology. Employees who returned to their home company after completing the training program contribute to accelerating and integrating digitalization.

In addition, TCO has an Atyrau Universities Engagement Program, which develops the competence of students of the Kh. Dosmukhamedov Atyrau State University and S. Utebayev Atyrau University of Oil and Gas and allows the company to obtain resources for key positions in Digital Department. TCO IT Department employees have been delivering lectures for students of these universities and conducting teacher internships for several years.

TCO continues to develop and contribute not only to the economy of the country, but also to the development of its digital technologies. The company shares its digital solutions of business problems with business partners, contractors, and shareholders, thereby expanding the company's values. ‘TCO has made tremendous progress in digital transformation. I am delighted with the capabilities of digital solutions we have already launched. It is obvious that digitalization has been and remains a key contributor to the development of our business,’ points out Kevin Lyon, General Director of Tengizchevroil.